Excavators are equipped with rotation devices essential for their operations, with the slewing bearing being a crucial component facilitating rotational movements. Responsible for supporting the machine's weight and bearing the operational loads, the slewing bearing is susceptible to common faults.

Due to the heavy-duty working conditions typically encountered by excavators, as well as the often extreme operating environments, slewing bearings are prone to various issues, notably the occurrence of abnormal noises. Understanding the causes behind such noises and conducting appropriate fault detection are essential steps.

Initially, it's essential to recognize that during high-speed rotation, slewing bearings may emit symmetrical noises attributed to the rolling of steel balls, which are considered normal. However, persistent and significant noises warrant attention.

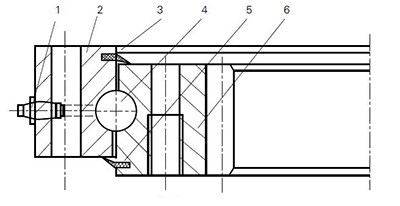

One common cause of such noises is uneven mounting surfaces or loose anchor bolts, leading to negative clearances in the rolling path and subsequent noise generation. Poor meshing of the pinion gears can also cause noise and may result in gear tooth breakage. Furthermore, loose anchor bolts can cause elastic deformation in the slewing bearing, resulting in negative clearances, necessitating immediate inspection and tightening.

Secondly, the presence of foreign particles inside the slewing bearing can cause non-periodic vibrations and hinder smooth rotation. Proper cleaning of the rolling elements, shaft, housing holes, and associated components before installation is crucial to prevent such issues.

Thirdly, lubrication problems may also lead to noise. Issues such as insufficient lubrication inside the raceway, uneven lubricant distribution, poor-quality lubricants prone to hardening, or incorrect lubricant selection can contribute to noise generation. Addressing such issues requires the application of suitable lubricants and immediate replenishment or replacement.

Fourthly, damaged sealing strips on the slewing bearing can compromise its sealing effectiveness, leading to lubricant leakage. Considerations such as the aging resistance and salt-resistant properties of the sealing strip material are essential in ensuring long-term performance.

Fifthly, noises may also result from surface cracks, indentations, or rust on the slewing bearing's raceway. These irregularities may manifest as regular vibrations similar to those of rivet bolts. Such noises can vary with installation and lubrication standards. Preventive measures include avoiding impacts on the rolling elements during installation and using high-viscosity lubricants.

Lastly, severe damage to the dovetail guide rails and rotating body of the slewing bearing during rotation can cause noise. In such cases, thorough inspection and maintenance of the slewing bearing are necessary.