On this page

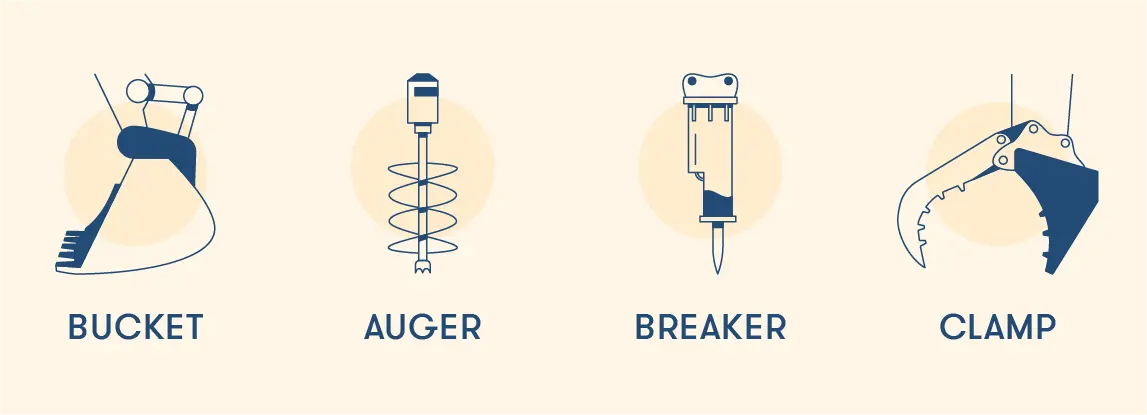

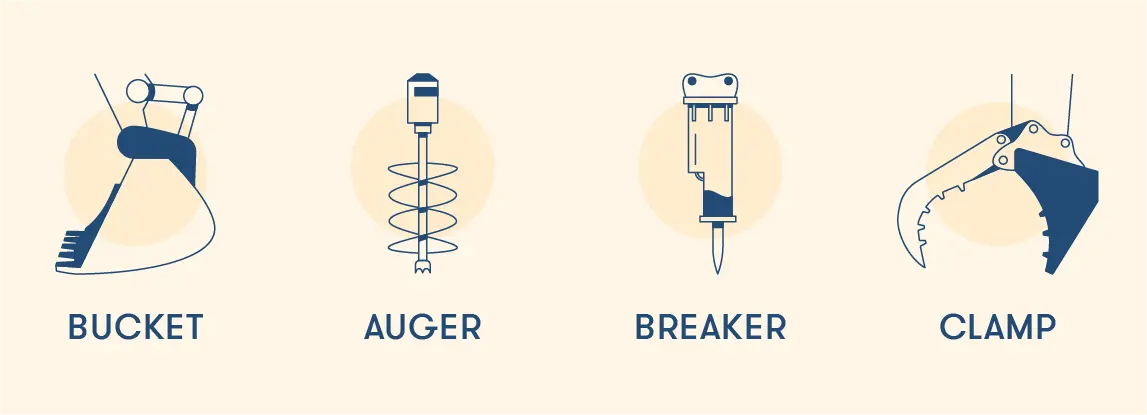

Small excavators have played an important role in mining, construction and other fields because of their excellent performance. Especially for small projects, small excavators are an ideal choice due to their versatility and flexibility. Equipped with different types of accessories, small excavators can expand their capabilities to meet a variety of job requirements, including trenching, drilling, moving soil and removing walls.

Choosing the right accessory for a small excavator can significantly improve operating efficiency. Here are some common accessories and their features:

The auger attachment is an efficient digging tool equipped with a metal screw for drilling holes in the ground. Its design features make it very easy to install on small excavators, especially suitable for handling hard and dense soils. Auger accessories are used in a wide range of engineering applications, such as post and pile drilling, infrastructure construction, stump removal and tree planting. Its key advantages include excellent drilling capabilities that enable it to complete tasks quickly and efficiently. Auger can not only maintain good working performance under a variety of soil conditions, but also has excellent adaptability and can handle geological materials with different hardness. In addition, the structural design of the auger attachment helps to reduce vibration during operation and improve operational stability, thereby increasing work efficiency.

A grab is a tool equipped with two opening and closing grippers, which are mainly used to collect, move or handle various objects. It is particularly suitable for handling heavy materials and demolition operations such as rock handling, tree clearing and log handling. The design of the grab allows it to handle objects of various shapes and sizes, increasing the flexibility and efficiency of the operation. Key benefits include efficient material handling capabilities, significantly improved safety and versatility. The high efficiency of the grab is reflected in its ability to quickly grasp and carry objects, reducing the waste of time in traditional methods. Its safety-enhancing design allows operators to be more stable when handling heavy objects, reducing operational risk.

The trenching attachment is a tool specifically designed for precision trench digging in environments that require specific depth and clear contours. It can handle a variety of complex geological conditions such as mixed soil, rocky terrain and frozen soil, and is often used in utility installation, drainage system construction and road construction projects. The main advantage of the trenching attachment is its excellent trench digging capability, which ensures that the depth and profile of the excavated trench meet the design requirements. Its design makes the excavation work more accurate and efficient, and can maintain good working performance under different soil conditions. In addition, the trenching attachment is adaptable and can cope with various geological challenges, further improving its application effect in complex operating environments.

The hydraulic thumb is an accessory that works synchronously with the bucket, simulating the function of the human thumb and facilitating the handling of various irregular objects. It is particularly suitable for forestry and rock handling applications, effectively helping operators pick up and secure objects such as stumps, rocks, logs, and concrete fragments. The design of the hydraulic thumb makes the picking and handling of objects simpler and more efficient, and its main advantages include simplified object picking process, versatility and improved ease of operation. By simulating the function of the thumb, the hydraulic thumb can flexibly deal with various irregular objects, reducing the labor intensity of the operator during the operation. In addition, its versatility enables it to be widely used in different types of jobs, improving the overall use value of the equipment.

When choosing a small excavator attachment, there are several key factors to consider. First of all, machine specifications are an important prerequisite for ensuring compatibility of accessories. The specifications of the accessories must match the model of the small excavator to ensure that they can work perfectly together and avoid the trouble caused by mismatching. Secondly, work requirements and frequency of use also affect the choice of accessories. For example, when dealing with debris, a grab or hydraulic thumb may be more effective than a regular bucket. Finally, budgetary considerations are an important factor in the selection of annexes. There is a wide variety of accessories for small excavators, and you can find suitable options according to your budget range.

In order to ensure the normal operation of small excavator accessories and extend the service life, regular maintenance and maintenance is essential. First, it is important to train operators who understand normal operating conditions and can identify potential problems for preventive maintenance. Secondly, follow the manufacturer's recommendations and refer to the manufacturer's maintenance manual for regular service. Before each use, check the accessories regularly for wear or damage, and clean the accessories regularly to remove dust and debris. Finally, make sure all moving parts are properly lubricated to prevent rust.

Small excavator accessories significantly enhance the versatility of the equipment, enabling it to adapt to different operational needs. Choosing the right accessories can improve work efficiency and ensure the safety and convenience of operation. Understanding the characteristics of each accessory and making a choice based on your specific needs will help you realize the full potential of your mini excavator and improve your overall level of operation.

The auger attachment is an efficient digging tool equipped with a metal screw for drilling holes in the ground. Its design features make it very easy to install on small excavators, especially suitable for handling hard and dense soils. Auger accessories are used in a wide range of engineering applications, such as post and pile drilling, infrastructure construction, stump removal and tree planting. Its key advantages include excellent drilling capabilities that enable it to complete tasks quickly and efficiently. Auger can not only maintain good working performance under a variety of soil conditions, but also has excellent adaptability and can handle geological materials with different hardness. In addition, the structural design of the auger attachment helps to reduce vibration during operation and improve operational stability, thereby increasing work efficiency.

A grab is a tool equipped with two opening and closing grippers, which are mainly used to collect, move or handle various objects. It is particularly suitable for handling heavy materials and demolition operations such as rock handling, tree clearing and log handling. The design of the grab allows it to handle objects of various shapes and sizes, increasing the flexibility and efficiency of the operation. Key benefits include efficient material handling capabilities, significantly improved safety and versatility. The high efficiency of the grab is reflected in its ability to quickly grasp and carry objects, reducing the waste of time in traditional methods. Its safety-enhancing design allows operators to be more stable when handling heavy objects, reducing operational risk.

The trenching attachment is a tool specifically designed for precision trench digging in environments that require specific depth and clear contours. It can handle a variety of complex geological conditions such as mixed soil, rocky terrain and frozen soil, and is often used in utility installation, drainage system construction and road construction projects. The main advantage of the trenching attachment is its excellent trench digging capability, which ensures that the depth and profile of the excavated trench meet the design requirements. Its design makes the excavation work more accurate and efficient, and can maintain good working performance under different soil conditions. In addition, the trenching attachment is adaptable and can cope with various geological challenges, further improving its application effect in complex operating environments.

The hydraulic thumb is an accessory that works synchronously with the bucket, simulating the function of the human thumb and facilitating the handling of various irregular objects. It is particularly suitable for forestry and rock handling applications, effectively helping operators pick up and secure objects such as stumps, rocks, logs, and concrete fragments. The design of the hydraulic thumb makes the picking and handling of objects simpler and more efficient, and its main advantages include simplified object picking process, versatility and improved ease of operation. By simulating the function of the thumb, the hydraulic thumb can flexibly deal with various irregular objects, reducing the labor intensity of the operator during the operation. In addition, its versatility enables it to be widely used in different types of jobs, improving the overall use value of the equipment.

When choosing a small excavator attachment, there are several key factors to consider. First of all, machine specifications are an important prerequisite for ensuring compatibility of accessories. The specifications of the accessories must match the model of the small excavator to ensure that they can work perfectly together and avoid the trouble caused by mismatching. Secondly, work requirements and frequency of use also affect the choice of accessories. For example, when dealing with debris, a grab or hydraulic thumb may be more effective than a regular bucket. Finally, budgetary considerations are an important factor in the selection of annexes. There is a wide variety of accessories for small excavators, and you can find suitable options according to your budget range.

In order to ensure the normal operation of small excavator accessories and extend the service life, regular maintenance and maintenance is essential. First, it is important to train operators who understand normal operating conditions and can identify potential problems for preventive maintenance. Secondly, follow the manufacturer's recommendations and refer to the manufacturer's maintenance manual for regular service. Before each use, check the accessories regularly for wear or damage, and clean the accessories regularly to remove dust and debris. Finally, make sure all moving parts are properly lubricated to prevent rust.

Small excavator accessories significantly enhance the versatility of the equipment, enabling it to adapt to different operational needs. Choosing the right accessories can improve work efficiency and ensure the safety and convenience of operation. Understanding the characteristics of each accessory and making a choice based on your specific needs will help you realize the full potential of your mini excavator and improve your overall level of operation.

The auger attachment is an efficient digging tool equipped with a metal screw for drilling holes in the ground. Its design features make it very easy to install on small excavators, especially suitable for handling hard and dense soils. Auger accessories are used in a wide range of engineering applications, such as post and pile drilling, infrastructure construction, stump removal and tree planting. Its key advantages include excellent drilling capabilities that enable it to complete tasks quickly and efficiently. Auger can not only maintain good working performance under a variety of soil conditions, but also has excellent adaptability and can handle geological materials with different hardness. In addition, the structural design of the auger attachment helps to reduce vibration during operation and improve operational stability, thereby increasing work efficiency.

A grab is a tool equipped with two opening and closing grippers, which are mainly used to collect, move or handle various objects. It is particularly suitable for handling heavy materials and demolition operations such as rock handling, tree clearing and log handling. The design of the grab allows it to handle objects of various shapes and sizes, increasing the flexibility and efficiency of the operation. Key benefits include efficient material handling capabilities, significantly improved safety and versatility. The high efficiency of the grab is reflected in its ability to quickly grasp and carry objects, reducing the waste of time in traditional methods. Its safety-enhancing design allows operators to be more stable when handling heavy objects, reducing operational risk.

The trenching attachment is a tool specifically designed for precision trench digging in environments that require specific depth and clear contours. It can handle a variety of complex geological conditions such as mixed soil, rocky terrain and frozen soil, and is often used in utility installation, drainage system construction and road construction projects. The main advantage of the trenching attachment is its excellent trench digging capability, which ensures that the depth and profile of the excavated trench meet the design requirements. Its design makes the excavation work more accurate and efficient, and can maintain good working performance under different soil conditions. In addition, the trenching attachment is adaptable and can cope with various geological challenges, further improving its application effect in complex operating environments.

The hydraulic thumb is an accessory that works synchronously with the bucket, simulating the function of the human thumb and facilitating the handling of various irregular objects. It is particularly suitable for forestry and rock handling applications, effectively helping operators pick up and secure objects such as stumps, rocks, logs, and concrete fragments. The design of the hydraulic thumb makes the picking and handling of objects simpler and more efficient, and its main advantages include simplified object picking process, versatility and improved ease of operation. By simulating the function of the thumb, the hydraulic thumb can flexibly deal with various irregular objects, reducing the labor intensity of the operator during the operation. In addition, its versatility enables it to be widely used in different types of jobs, improving the overall use value of the equipment.

When choosing a small excavator attachment, there are several key factors to consider. First of all, machine specifications are an important prerequisite for ensuring compatibility of accessories. The specifications of the accessories must match the model of the small excavator to ensure that they can work perfectly together and avoid the trouble caused by mismatching. Secondly, work requirements and frequency of use also affect the choice of accessories. For example, when dealing with debris, a grab or hydraulic thumb may be more effective than a regular bucket. Finally, budgetary considerations are an important factor in the selection of annexes. There is a wide variety of accessories for small excavators, and you can find suitable options according to your budget range.

In order to ensure the normal operation of small excavator accessories and extend the service life, regular maintenance and maintenance is essential. First, it is important to train operators who understand normal operating conditions and can identify potential problems for preventive maintenance. Secondly, follow the manufacturer's recommendations and refer to the manufacturer's maintenance manual for regular service. Before each use, check the accessories regularly for wear or damage, and clean the accessories regularly to remove dust and debris. Finally, make sure all moving parts are properly lubricated to prevent rust.

Small excavator accessories significantly enhance the versatility of the equipment, enabling it to adapt to different operational needs. Choosing the right accessories can improve work efficiency and ensure the safety and convenience of operation. Understanding the characteristics of each accessory and making a choice based on your specific needs will help you realize the full potential of your mini excavator and improve your overall level of operation.

The auger attachment is an efficient digging tool equipped with a metal screw for drilling holes in the ground. Its design features make it very easy to install on small excavators, especially suitable for handling hard and dense soils. Auger accessories are used in a wide range of engineering applications, such as post and pile drilling, infrastructure construction, stump removal and tree planting. Its key advantages include excellent drilling capabilities that enable it to complete tasks quickly and efficiently. Auger can not only maintain good working performance under a variety of soil conditions, but also has excellent adaptability and can handle geological materials with different hardness. In addition, the structural design of the auger attachment helps to reduce vibration during operation and improve operational stability, thereby increasing work efficiency.

A grab is a tool equipped with two opening and closing grippers, which are mainly used to collect, move or handle various objects. It is particularly suitable for handling heavy materials and demolition operations such as rock handling, tree clearing and log handling. The design of the grab allows it to handle objects of various shapes and sizes, increasing the flexibility and efficiency of the operation. Key benefits include efficient material handling capabilities, significantly improved safety and versatility. The high efficiency of the grab is reflected in its ability to quickly grasp and carry objects, reducing the waste of time in traditional methods. Its safety-enhancing design allows operators to be more stable when handling heavy objects, reducing operational risk.

The trenching attachment is a tool specifically designed for precision trench digging in environments that require specific depth and clear contours. It can handle a variety of complex geological conditions such as mixed soil, rocky terrain and frozen soil, and is often used in utility installation, drainage system construction and road construction projects. The main advantage of the trenching attachment is its excellent trench digging capability, which ensures that the depth and profile of the excavated trench meet the design requirements. Its design makes the excavation work more accurate and efficient, and can maintain good working performance under different soil conditions. In addition, the trenching attachment is adaptable and can cope with various geological challenges, further improving its application effect in complex operating environments.

The hydraulic thumb is an accessory that works synchronously with the bucket, simulating the function of the human thumb and facilitating the handling of various irregular objects. It is particularly suitable for forestry and rock handling applications, effectively helping operators pick up and secure objects such as stumps, rocks, logs, and concrete fragments. The design of the hydraulic thumb makes the picking and handling of objects simpler and more efficient, and its main advantages include simplified object picking process, versatility and improved ease of operation. By simulating the function of the thumb, the hydraulic thumb can flexibly deal with various irregular objects, reducing the labor intensity of the operator during the operation. In addition, its versatility enables it to be widely used in different types of jobs, improving the overall use value of the equipment.

When choosing a small excavator attachment, there are several key factors to consider. First of all, machine specifications are an important prerequisite for ensuring compatibility of accessories. The specifications of the accessories must match the model of the small excavator to ensure that they can work perfectly together and avoid the trouble caused by mismatching. Secondly, work requirements and frequency of use also affect the choice of accessories. For example, when dealing with debris, a grab or hydraulic thumb may be more effective than a regular bucket. Finally, budgetary considerations are an important factor in the selection of annexes. There is a wide variety of accessories for small excavators, and you can find suitable options according to your budget range.

In order to ensure the normal operation of small excavator accessories and extend the service life, regular maintenance and maintenance is essential. First, it is important to train operators who understand normal operating conditions and can identify potential problems for preventive maintenance. Secondly, follow the manufacturer's recommendations and refer to the manufacturer's maintenance manual for regular service. Before each use, check the accessories regularly for wear or damage, and clean the accessories regularly to remove dust and debris. Finally, make sure all moving parts are properly lubricated to prevent rust.

Small excavator accessories significantly enhance the versatility of the equipment, enabling it to adapt to different operational needs. Choosing the right accessories can improve work efficiency and ensure the safety and convenience of operation. Understanding the characteristics of each accessory and making a choice based on your specific needs will help you realize the full potential of your mini excavator and improve your overall level of operation.